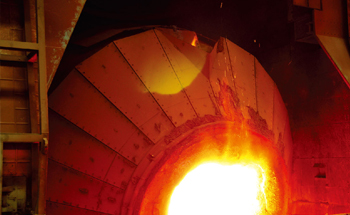

Alloy Cast Steel Rolls (AS)

Alloy cast steel rolls are made of high quality steel melted with variable frequency furnace and finished with advanced foundry and heat treatment technologies. Our rolls have mechanical properties of high tensile strength, excellent resistance to fire crack, high wearability and toughness. These rolls are mainly composed of pearlite (or temper sorbite) in the microstructure.

Table.1 Chemical Composition %

| Symbol | C | Si | Mn | Cr | Ni | Mo |

| AS60 | 0.55-0.65 | 0.20-0.45 | 0.90-1.20 | 0.80-1.20 | - | 0.20-0.45 |

| AS65I | 0.60-0.70 | 0.20-0.60 | 0.50-0.80 | 0.80-1.20 | 0.20-0.50 | 0.20-0.45 |

| AS70Ⅱ | 0.65-0.75 | 0.20-0.45 | 1.40-1.80 | - | - | 0.20-0.45 |

| AS75 | 0.70-0.80 | 0.20-0.45 | 0.60-0.90 | 0.75-1.00 | - | 0.20-0.45 |

| AS75Ⅰ | 0.70-0.80 | 0.20-0.70 | 0.70-1.10 | 0.80-1.60 | ≥0.20 | 0.20-0.60 |

| Cr4 | 0.40-0.70 | 0.20-0.60 | 0.70-1.20 | 3.00-5.00 | ≥0.50 | 0.40-1.00 |

Table.2 Prosperities&Application

| Symbol | Hardness HS |

Tensile Strength MPa |

Dimension MM |

Unit N.W KGS |

Application |

| AS60 | 35-50 | ≥650 | ¢600-1600 | 1000-50000 | Blooming and slabbing mills,roughing stands of large section mills;Roughing stands of bar and wire mills,breakdown rolls for rail and section universal mills |

| AS65I | 35-45 | ≥650 | |||

| AS70Ⅱ | 35-45 | ≥680 | |||

| AS75 | 35-50 | ≥680 | |||

| AS75Ⅰ | 35-50 | ≥700 | |||

| Cr4 | 50-65 | ≥700 |

|

Sitemap

Sitemap